Specialized in engine anodes Exporter India, Excellent Quality in engine anodes With Low Price, engine anodes Inquire, Wide Range engine anodes, Get a Live Quote Now for engine anodes, engine anodes available here, engine anodes Best Factory, engine anodes Competitive Price Here

Frequently Asked Questions

Q: What is a Sacrificial Anode?

A: A sacrificial anode is exactly what it says, sacrificial. An anode is a metal or a composition of metals that are designed to protect another metal, which is lower on the electro-negativity series chart. Good examples are: zinc and aluminum, these metals are higher on the electro-negativity series chart than steel, and will give up electrons to protect the primary metal -steel.

Q: I purchased anodes from a company not registered with ISO, and they lasted longer. WHY?

A: Were they anodes or were they recycled unknown metals full of contamination? Were they lead? Anodes are sacrificial and are meant to undergo a reduction in size due to the process of electrolysis. Sometimes anodes will disappear if the ship has electrical grounds that need to be repaired. Research has shown that a longer lasting anode does not necessarily mean a better anode.

Q: Why can I not use Lead on a steel ship?

A: Lead as an anode should not be used on steel because it has a much lower number on the electro-negativity chart. If reversed, then you have created a problem whereas the ship acts as the anode to protect the lead.

Q: What materials can be found in an anode?

A: Generally, anodes are used to protect other items such as nickel, silver, brass, etc., However, the anodes Rajesh Metal Syndicate manufactures are generally for both steel structures and steel ships used in salt water. For these seawater applications Rajesh Metal Syndicate follows International Standards. The anodes made by Rajesh Metal Syndicate consist of Zinc, Aluminum, Indium, and Cadmium, which are carefully measured and mixed to form a better than "raw" material" anode. All materials used by Rajesh Metal Syndicate are 99% pure, and are not recycled materials. When you purchase anodes from Rajesh Metal Syndicate, you are receiving an ISO Certified product.

Q - What would happen to my Vessel if I never used Anodes?

A - If there are no Sacrificial Anodes present, the Electrolysis process would still continue and would attack the weakest areas which are Exposed Steel Areas, Bead Welding, and any other areas with Dis-similar metals, such as around the Stern Gland Stern Tube areas.

Q - What is the Difference between Zinc and Aluminum Anodes? Why are they Sacrificial?

A - Both are low on the electro-negativity series chart. in comparison with Steel. Steel is the most common Metal used for Ships, Wharfs, Offshore Structures, etc..., so where there is continuing Electrolysis in Water (especially Salt Water), a Dissimilar Metal or Impressed Current has to be present to Give up (Sacrificial) Electrons to Neutralize the Current Created. Zinc is a little Cheaper Metal than Aluminum and does not last as long as in the same Electrolysis conditions. Aluminum is more expensive, but last longer. It generally works out to be the same cost over the same duration.

Q - Why does the Anodes not last very long, but I have a good Painting system on my Vessel?

A - You may have another problem on your Ship! If you have an Electrical Ground on your Ship, your Hull is the Ground, and the Steel will deteriorate must faster.

Q - Where do you generally place anodes?

A - Anywhere that a Metal is submerged or subject to a Harsh environment, and the Medium that it is exposed to requires Electrons. Most Common areas for Anodes are found on the Ships Hull, Ships Ballast Tanks, Steel Structural Wharfs, Offshore Structures, and even on Modern Automobiles.

Q - Is there some other way to protect Steel besides Sacrificial Anodes?

A - Yes. Another way to protect besides Sacrificial Anodes is called Impressed Current Systems. This option is very expensive and not very common. This is a System where Electricity is actually supplied to the Steel Structure in very low doses, and carefully regulated. These systems are generally found on Ice Breaking Ships, Naval Ships, and Steel Structures submerged permanently in Salt Water.

Q - Why does some anodes from different companies last much longer than from other Companies?

A - Are you sure what you purchased as an Anodes is actually an Anode? Ask your supplier for a copy of the Chemical Composition Chart. What you bought may not even be an anode! If you do have what you think is an Anode on your Steel, and it is not disappearing, and your Welding, and Steel in different areas are disappearing, then your Steel Structure is the ANODE!!! This is a great cost to a vessel owner, therefore we recommend you ensure purchasing certified quality Anodes.

Marine Corrosion Specialist

| Rajesh Metal Syndicate Manufacturers / Exporters / Suppliers & Stockist of Zinc Hull Anodes, Aluminium Hull Anodes, Zinc Tank Anodes, Aluminium Tank Anodes, Zinc Rod, Zinc Pencil, Zinc Strip, Zinc Engine Anodes, Gun Metal & P. Bronze Castings, Brass Plugs, Stainless Steel Pipes, Stainless Steel Shafts Etc. | ||

| Zinc Hull Anodes | Aluminium Hull Anodes | Zinc Tank Anodes |

|

|

|

| Aluminium Tank Anodes | Zinc Rod | Zinc Pencil |

|

|

|

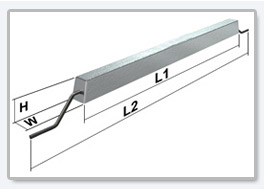

| Zinc Strip | Zinc Engine Anodes | Gun Metal & P. Bronze Castings |

|

|

|

| Brass Plugs | Stainless Steel Pipes | Stainless Steel Shafts |

|

|

|

| Rajesh Metal Syndicate Manufacturers / Exporters / Suppliers & Stockist of Zinc Hull Anodes, Aluminium Hull Anodes, Zinc Tank Anodes, Aluminium Tank Anodes, Zinc Rod, Zinc Pencil, Zinc Strip, Zinc Engine Anodes, Gun Metal & P. Bronze Castings, Brass Plugs, Stainless Steel Pipes, Stainless Steel Shafts Etc. | ||